- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

KHS is expanding its process engineering portfolio to include a further future-proof filtration setup: alongside the proven Innopro Getra ECO diatomaceous earth system, an alternative membrane filtration system has been developed in the Innopro Ecoclear. Together with Innopro Ecostab beer stabilization, the systems provider can now supply its customers with a full filter cellar from a single source. KHS thus offers holistic, customized systems tailored to individual brewery requirements.

Decisive addition to the product range: with the Innopro Ecoclear KHS has added its first system for membrane filtration to its engineering spectrum. The technology has been developed together with a well-known partner. “By expanding our portfolio in this way, we’re consciously catering for the interface between the fermentation cellar and filling on the line. We score with maximum product quality in all of these areas,” says Tobias Cherdron, process engineering product manager at KHS.

Proven universal filter system

Filtration serves to separate haze substances from a wide variety of beverages, such as yeasts from the fermentation process and proteins in beer. KHS already has a long-established, reliable low-maintenance system on the market in the Innopro Getra ECO for precisely this purpose that gets perfect results with diatomaceous earth or other regenerative filter media. Up to 1,000 hectoliters of beer per hour can be filtered using this proven precoating method.

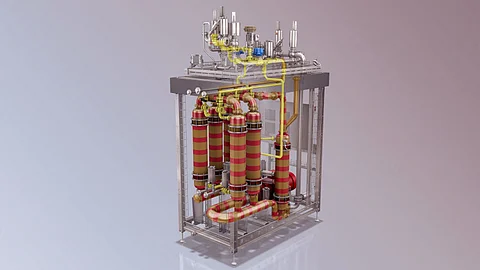

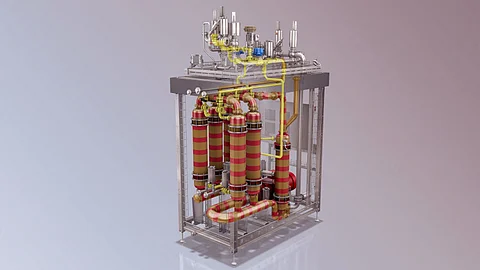

Modular KHS membrane filter design increases flexibility

As opposed to the above, KHS’ alternative membrane filtering technology makes use of a modular system. This comprises four modules that each process up to 72 hectoliters an hour. Yeast particles and solids are deposited in these while the filling product passes through the membrane module in a crossflow that keeps the liquid in constant motion. Its modularity makes the system extremely flexible. It can thus be expanded depending on the filling quantity and capacity of the optional downstream beer stabilization process. KHS provides a suitable system to this end with its Ecostab series that comes in three different general versions: variant S for stabilization of up to 75 hectoliters of beverage per hour, variant B for up to 240 hectoliters an hour and variant C for a maximum of 600 hectoliters every 60 minutes. The output of the latter is such that it can be perfectly combined with membrane filtration. Furthermore, both KHS filtration principles are compatible with the process engineering manufactured by other suppliers and can be integrated into appropriate automation environments.

The variant beverage producers opt for – with all its pros and cons – ultimately depends on their exact requirement profile. The biggest difference is that diatomaceous earth is used in what is known as the batch process. Here, only a certain amount of beverage can be filled before the system and thus filtration regularly shut down for around three hours. During this time diatomaceous earth and yeast are extracted backwards through the filter vessel in order to clean it and reboot the process. “This is an intermittent filter system,” says Cherdron.

Continuous flow to the filler

In contrast, membrane filtration modules are easier to clean, with the yeasts flushed out. In any one system only three of the four modules work at the same time, with the fourth running through a cleaning cycle. Differential switching between the individual systems ensures a constant supply to the downstream equipment. “The aim is to provide a continuous beverage supply through filigree modularization. The amount scheduled for stabilization and subsequent further processing stays the same,” Cherdron explains. Besides being able to save on buffer volume, the installed membrane surface area is also minimized. It is of course possible to use membrane filtration in batch operation – tailored to individual specifications.

A further benefit of the modular system lies in the parts used. “We can make use of standard components for this machine. This allows us to give our customers fast service, such as with the replacement of spare parts,” states Cherdron. The product manager also sees the advantages in Innopro Getra ECO precoat filtration, however. “You don’t have to constantly supply the line with beer, for instance. With the help of diatomaceous earth filtration users are more flexible as regards both production planning and product quality.”

Click HERE to subscribe to our FREE Weekly Newsletter