- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

A new version of Ishida’s market-leading remote production monitoring and reporting solution, Sentinel 5.0, is set to be the one of the highlights of this year’s Gulfood Manufacturing exhibition in Dubai. The company is also showcasing a range of its weighing, packing and quality control solutions, including its recently launched IX-PD X-ray inspection system, which breaks new ground in detection capabilities.

Gulfood Manufacturing is taking place in Dubai on 5-7 November at the Dubai World Trade Centre, with Ishida based in Hall 3, stand C3-4. The world-leader in weighing, packing and quality control equipment is demonstrating how its brand-new Sentinel 5.0 software combines machine performance monitoring with comprehensive data capture to give food manufacturers a smarter, more in-depth analysis of their entire food production line.

The technology, which aligns with Industry 5.0 principles of human-machine collaboration, enables food manufacturers and packers to operate their lines at maximum performance and efficiency. Through greater access to critical data, they can achieve better planning and high levels of preventative maintenance that avoid unnecessary and unwanted downtime.

Talking about the launch, Matt Eastham, general manager, Middle East at Ishida Europe, said, “We are very much looking forward to Gulfood Manufacturing this year, as it will be a landmark occasion where we unveil how the food manufacturing industry can readily implement Industry 5.0 principles within their operations."

“In simplest terms, Industry 5.0 strives for better collaboration between people and machinery, and we’re showing how we’re already well down this pathway with Sentinel 5.0. It is the successor to our already very popular Sentinel 4.0 software, and crucially, allows integrated connectivity with both Ishida and non-Ishida machines. In practice, this means manufacturers have more joined up, smarter thinking, with our remote monitoring system putting connected technology at their fingertips. Operators can track performance and trace issues at every point during the food production line, which in turn allows them to pinpoint areas for improvement, unlock efficiencies, and minimize chances of non-compliance.”

As part of the upgrade, enhancements include a new user interface, and the software also automatically checks for E-mark compliance and Digital HACCP conformance.

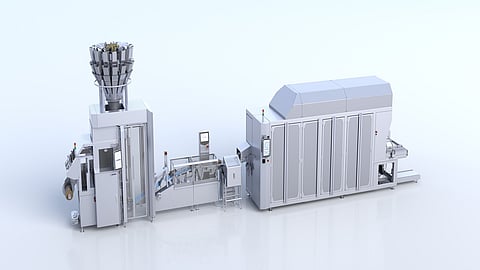

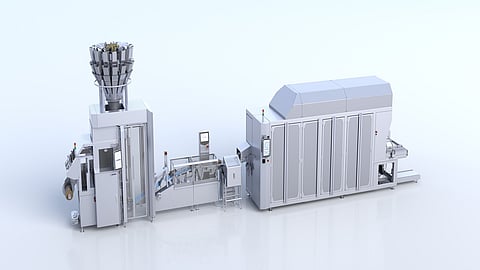

Alongside the Sentinel 5.0 launch, Ishida is also showcasing a variety of its models from its extensive portfolio, which underline the breadth of the company’s food packing automation solutions. These include a high-performance snack food packing system for pillow packs, three multihead weigher models that demonstrate how Ishida can tailor its technology to the needs of many different markets and applications, an entry-level checkweigher, and a further example of advanced X-ray inspection technology.

The standout model of the multihead weighers on show is the CCW-AS-214, which significantly boosts productivity, hygiene, and profitability, while providing a 20% energy reduction and lower noise. The Ishida Micro, meanwhile, is the world’s smallest multihead weigher and ideal for weighing high-value products at ultra-low target weights with outstanding accuracy of 0.01g. The 8-head Ishida Fresh Food Weigher (FFW) efficiently weighs and packs both very sticky and bruise-sensitive products, reducing giveaway to under 1% and cutting labor costs by three operators per shift.

The recently launched Ishida IX-PD X-ray inspection system incorporates new sensor and image processing technology that achieves the highest levels of detection sensitivity. This enables the machine to offer enhanced detection at high productivity rates for low-density items including bones in fish fillets and minute foreign bodies such as stainless steel wires. In addition, the IX-PD can reliably detect foreign bodies in applications where products are overlapping or standing up in a pack.

Matt said, “More and more, food manufacturers are realizing the benefits that innovative X-ray inspection systems can offer. The food sector remains at risk of product recalls caused by foreign body contamination, which can have long-lasting implications for a brand’s reputation and its bottom line, not to mention the risk it poses to people and animals. With the latest X-ray machines from Ishida, these outcomes can be easily avoided, allowing manufacturers to identify quality issues in real-time, safeguarding against food safety issues and protecting their brand.”

Click HERE to subscribe to our FREE Weekly Newsletter