- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

Photo - Multivac

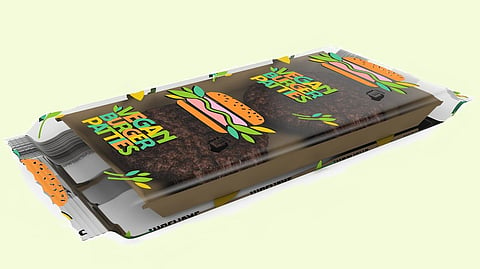

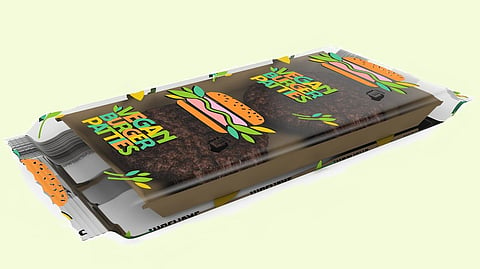

MULTIVAC is launching its W 500 onto the market as a universal flowpacking solution, which offers a high level of flexibility for packing a wide range of food products. The new flowpacker, which is designed for a wide spectrum of applications and products, supports the use of sustainable films and paper-based materials. It will be presented to the public for the first time at two leading trade fairs, Anuga FoodTec 2022 (Hall 8.1, Stand C010) and IFFA 2022 (Hall 11.1, Stand B11), and it will be the heart of a high-performance line for the automatic packing of burgers in a pillow pack.

The pillow pack is traditionally one of the primary solutions for the secure and attractive packaging of food products, such as meat and sausages, cheese, snacks, bakery products and fruit. Pillow packs are also widely used to protect industrial and pharmaceutical products. The low material input and the ease of integration into other processes are the main features of this packaging solution, and the flowpacker perfectly complements the current MULTIVAC product range.

W 500 horizontal flowpacker

Photo - Multivac

With the addition of the new W 500 horizontal flowpacker, MULTIVAC is now expanding its equipment range and turning its extensive technical and packaging expertise to a new area of application. “Thanks to the new W 500 in our product range, we can now offer our customers an even greater choice of solutions to meet their exact requirements. And with the W 500 as with all our other equipment, we can offer the right packaging materials, so that the pillow packs are environmentally-friendly and recyclable. Being able to offer the complete package is very important to us, and we will continue to expand this, so that we can cover all the future requirements of our customers,” explains Kim Hüther, executive vice president of Tray & Pouch Packaging at MULTIVAC. “The main features of the W 500 flowpacker are its easy operation, cleaning and maintenance, as well as an attractive price-to-performance ratio. It can be used as a stand-alone solution, or it can be integrated into an automated line - as will be seen at the trade fairs.”

The new solution is ideally suited to the sustainable packaging of products such as minced meat, burgers, cevapcici, sausages, cheese and frozen fish. And bakery products such as baguettes, croissants and pizzas, as well as many types of fruit and vegetables, can also be packaged securely in pillow packs with very efficient material usage.

The robust machine, which is built to MULTIVAC's innovative Hygienic Design, is characterised by its high level of efficiency and precision, as well as its user-friendliness, reliability, cost-effectiveness and high output. Precise servo drive technology ensures that maximum speed and optimum process control are achieved. Products with a maximum width of 200 mm and a height of up to 120 mm can easily be packed - with or without a tray. The other features include the independent speed setting of the rollers for crease-free longitudinal sealing, the extremely reliable cross sealing thanks to precise and recipe-based control of sealing temperature and pressure, as well as an integrated gas analysis system for MAP packing with modified atmosphere. Offering an output of up to 120 packs per minute or a film speed of up to 30 metres/min, the W 500 is among the best performing box-motion flowpacking solutions on the market. It is also possible to integrate marking or labelling solutions seamlessly.

All process and pack parameters such as type of product, pack format, sealing pressure and temperature are recipe-based, and they can be set and called up with just a few clicks on the user-friendly HMI. Product changes can also be performed in a very short period of time. The machine components are easily accessible for cleaning and maintenance.

On the MULTIVAC exhibition stand ...

The high-performance W 500 flowpacker is the core of an automated, space-saving line. A centrifuge converges the burgers into a single line on one transport conveyor, while the cardboard trays are denested onto another conveyor running in parallel. A handling module loads the burgers into the cardboard trays. The filled trays then run into the packaging machine, where they are packed under modified atmosphere. An inline labeller then applies a label from above to the packs.

Click HERE to subscribe to our FREE Weekly Newsletter