- Home

- EventsEvents

- Product Launches

- CategoriesCategories

- Advertise

- Opinion

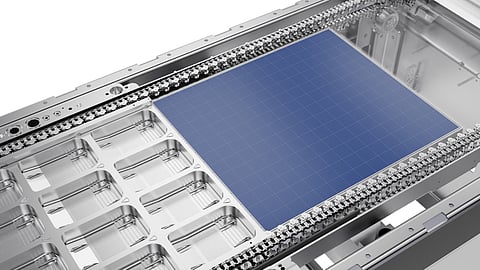

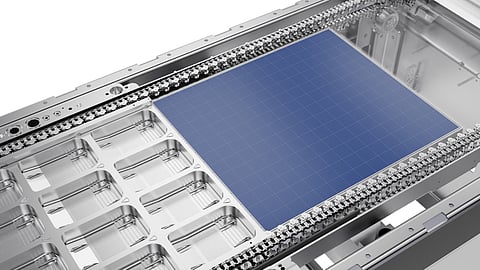

GEA PowerHeat M – The new matrix heating system placed in the GEA PowerPak thermoformer

Photo - GEA

Monomaterials that can be 100% recycled place special demands on the heating systems required for the thermoforming process. GEA PowerHeat makes using these materials easier and safer without sacrificing performance. In terms of sustainability, the new system also impresses with energy-saving heating, without compromising on the high standard of packaging quality and product safety. The new matrix heating system in the GEA Thermoformer was developed in close cooperation with technology partner Watttron and tested for market launch with the Wolf Group, a food manufacturer and pilot customer of GEA.

Zone heating system

Mono-materials place special demands on heating systems. The GEA PowerHeat Z zone heating system evenly regulates the temperature in different zones of the heating plates independently of each other, ensuring that each package is evenly formed – right up to the edges. The benefits of energy-efficient heating come to the fore when using mono-packaging materials such as mono PP or mono PE.

A cold cut packaging made of resource-saving mono-materials from the Wolf group of companies

Photo - GEA

Matrix heating system

The GEA PowerHeat M matrix heating system can be used to set customized package-specific temperature profiles. It is a solution that proves particularly effective when using multilayer films as well as mono-materials. This is because the film thickness of the packaging materials can be significantly reduced without negatively impacting packaging functionalities such as residual film thickness and barrier properties. In addition, energy costs are considerably reduced since long heating times are eliminated and operating temperatures are rapidly reached. Extremely fast control processes and precise adjustment of temperature fields avoid the temperature overshoots of traditional heating systems, which are detrimental to many packaging materials. The new heating systems can also significantly increase packaging output and capacity.

GEA at IFFA, Hall 8, Booth G20

Click HERE to subscribe to our FREE Weekly Newsletter